Revealing the Hidden Universe with Full-shell X-ray Optics at NASA MSFC

The study of X-ray emission from astronomical objects reveals secrets about the Universe at the largest and smallest spatial scales. Celestial X-rays are produced by black holes consuming nearby stars, emitted by the million-degree gas that traces the structure between galaxies, and can be used to predict whether stars may be able to host planets hospitable to life. X-ray observations have shown that most of the visible matter in the universe exists as hot gas between galaxies and have conclusively demonstrated that the presence of “dark matter” is needed to explain galaxy cluster dynamics, that dark matter dominates the mass of galaxy clusters, and that it governs the expansion of the cosmos.

X-ray observations also enable us to probe mysteries of the Universe on the smallest scales. X-ray observations of compact objects such as white dwarfs, neutron stars, and black holes allow us to use the Universe as a physics laboratory to study conditions that are orders of magnitude more extreme in terms of density, pressure, temperature, and magnetic field strength than anything that can be produced on Earth. In this astrophysical laboratory, researchers expect to reveal new physics at the subatomic scale by conducting investigations such as probing the neutron star equation of state and testing quantum electrodynamics with observations of neutron star atmospheres. At NASA’s Marshall Space Flight Center, a team of scientists and engineers is building, testing, and flying innovative optics that bring the Universe’s X-ray mysteries into sharper focus.

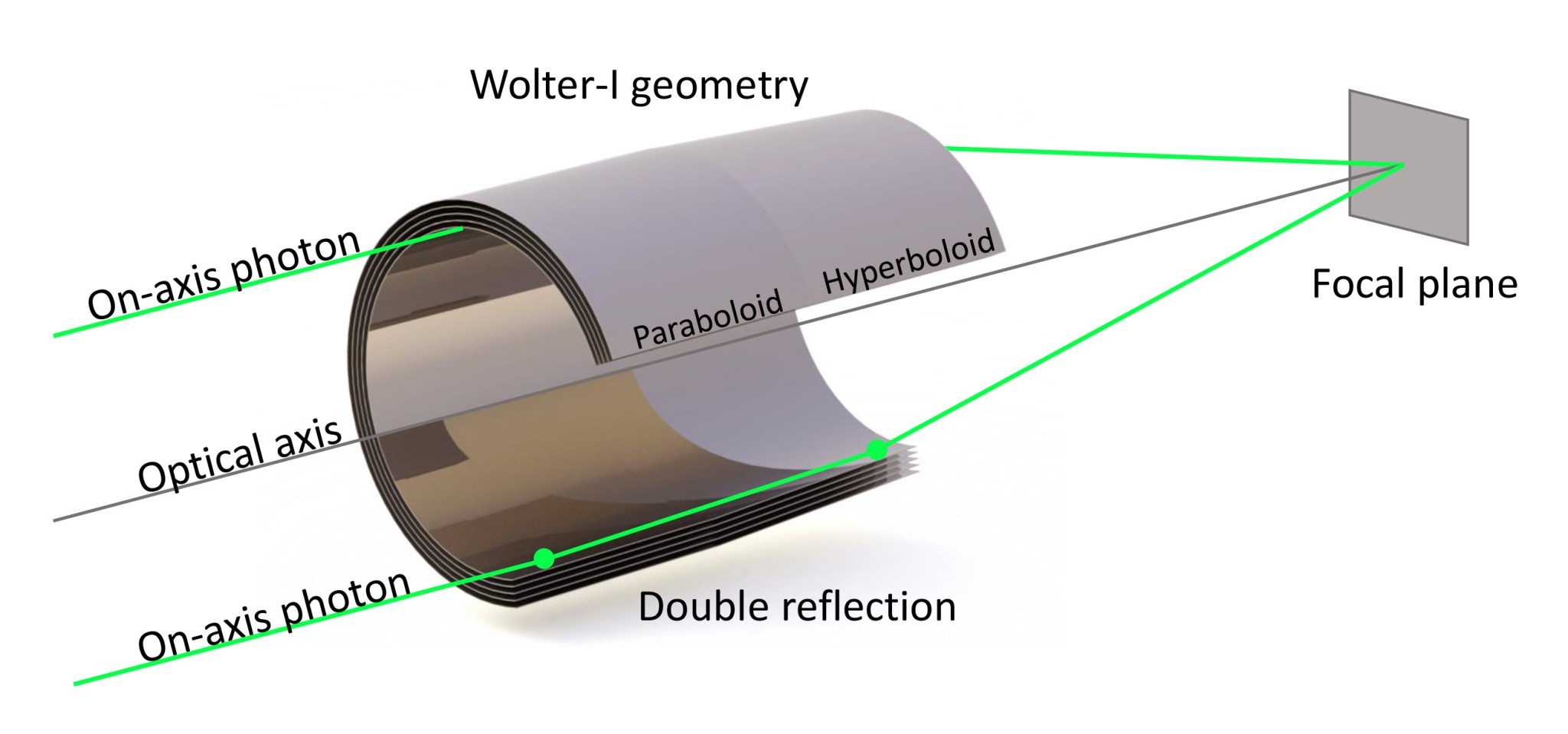

Unlike optical telescopes that create images by reflecting or refracting light at near-90-degree angles (normal incidence), focusing X-ray optics must be designed to reflect light at very small angles (grazing incidence). At normal incidence, X-rays are either absorbed by the surface of a mirror or penetrate it entirely. However, at grazing angles of incidence, X-rays reflect very efficiently due to an effect called total external reflection. In grazing incidence, X-rays reflect off the surface of a mirror like rocks skipping on the surface of a pond.

A classic design for astronomical grazing incidence optics is the Wolter-I prescription, which consists of two reflecting surfaces, a parabola and hyperbola (see figure below). This optical prescription is revolved around the optical axis to produce a full-shell mirror (i.e., the mirror spans the full circumference) that resembles a gently tapered cone. To increase the light collecting area, multiple mirror shells with incrementally larger diameters and a common focus are fabricated and nested concentrically to comprise a mirror module assembly (MMA).

Focusing optics are critical to studying the X-ray universe because, in contrast to other optical systems like collimators or coded masks, they produce high signal-to-noise images with low background noise. Two key metrics that characterize the performance of X-ray optics are angular resolution, which is the ability of an optical system to discriminate between closely spaced objects, and effective area, which is the light collecting area of the telescope, typically quoted in units of cm2. Angular resolution is typically measured as the half-power diameter (HPD) of a focused spot in units of arcseconds. The HPD encircles half of the incident photons in a focused spot and measures the sharpness of the final image; a smaller number is better.

NASA Marshall Space Flight Center (MSFC) has been building and flying lightweight, full-shell, focusing X-ray optics for over three decades, always meeting or exceeding angular resolution and effective area requirements. MSFC utilizes an electroformed nickel replication (ENR) technique to make these thin full-shell X-ray optics from nickel alloy.

X-ray optics development at MSFC began in the early 1990s with the fabrication of optics to support NASA’s Advanced X-ray Astrophysics Facility (AXAF-S) and then continued via the Constellation-X technology development programs. In 2001, MSFC launched a balloon payload that included two modules each with three mirrors, which produced the first focused hard X-ray (>10 keV) images of an astrophysical source by imaging Cygnus X-1, GRS 1915, and the Crab Nebula. This initial effort resulted in several follow-up missions over the next 12 years, and became known as the High Energy Replicated Optics (HERO) balloon program.

In 2012, the first of four sounding rocket flights of the Focusing Optics X-ray Solar Imager (FOXSI) flew with MSFC optics onboard, producing the first focused images of the Sun at energies greater than 5 keV. In 2019 the Astronomical Roentgen Telescope X-ray Concentrator (ART-XC) instrument on the Spectr-Roentgen-Gamma Mission launched with seven MSFC-fabricated X-ray MMAs, each containing 28 mirror shells. ART-XC is currently mapping the sky in the 4-30 keV hard X-ray energy range, studying exotic objects like neutron stars in our own galaxy as well as active galactic nuclei, which are spread across the visible universe. In 2021, the Imaging X-ray Polarimetry Explorer (IXPE), flew and is now performing extraordinary science with an MSFC-led team using three, 24-shell MMAs that were fabricated and calibrated in-house.

Most recently, in 2024, the fourth FOXSI sounding rocket campaign launched with a high-resolution MSFC MMA. The optics achieved 9.5 arcsecond HPD angular resolution during pre-flight test with an expected 7 arcsecond HPD in gravity-free flight, making this the highest angular resolution flight observation made with a nickel-replicated X-ray optic. Currently MSFC is fabricating an MMA for the Rocket Experiment Demonstration of a Soft X-ray (REDSoX) polarimeter, a sounding rocket mission that will fly a novel soft X-ray polarimeter instrument to observe active galactic nuclei. The REDSoX MMA optic will be 444 mm in diameter, which will make it the largest MMA ever produced by MSFC and the second largest replicated nickel X-ray optic in the world.

The ultimate performance of an X-ray optic is determined by errors in the shape, position, and roughness of the optical surface. To push the performance of X-ray optics toward even higher angular resolution and achieve more ambitious science goals, MSFC is currently engaged in a fundamental research and development effort to improve all aspects of full-shell optics fabrication.

Given that these optics are made with the Electroformed Nickel Replication technique, the fabrication process begins with creation of a replication master, called the mandrel, which is a negative of the desired optical surface. First, the mandrel is figured and polished to specification, then a thin layer of nickel alloy is electroformed onto the mandrel surface. Next, the nickel alloy layer is removed to produce a replicated optical shell, and finally the thin shell is attached to a stiff holding structure for use.

Each step in this process imparts some degree of error into the final replicated shell. Research and development efforts at MSFC are currently concentrating on reducing distortion induced during the electroforming metal deposition and release steps. Electroforming-induced distortion is caused by material stress built into the electroformed material as it deposits onto the mandrel. Decreasing release-induced distortion is a matter of reducing adhesion strength between the shell and mandrel, increasing strength of the shell material to prevent yielding, and reducing point defects in the release layer.

Additionally, verifying the performance of these advanced optics requires world-class test facilities. The basic premise of testing an optic designed for X-ray astrophysics is to place a small, bright X-ray source far away from the optic. If the angular size of the source, as viewed from the optic, is smaller than the angular resolution of the optic, the source is effectively simulating X-ray starlight. Due to the absorption of X-rays by air, the entire test facility light path must be placed inside a vacuum chamber.

At MSFC, a group of scientists and engineers operate the Marshall 100-meter X-ray beamline, a world-class end-to-end test facility for flight and laboratory X-ray optics, instruments, and telescopes. As per the name, it consists of a 100-meter-long vacuum tube with an 8-meter-long, 3-meter-diameter instrument chamber and a variety of X-ray sources ranging from 0.25 – 114 keV. Across the street sits the X-Ray and Cryogenic Facility (XRCF), a 527-meter-long beamline with an 18-meter-long, 6-meter-diameter instrument chamber. These facilities are available for the scientific community to use and highlight the comprehensive optics development and test capability that Marshall is known for.

Within the X-ray astrophysics community there exist a variety of angular resolution and effective area needs for focusing optics. Given its storied history in X-ray optics, MSFC is uniquely poised to fulfill requirements for large or small, medium- or high-angular-resolution X-ray optics. To help guide technology development, the astrophysics community convenes once per decade to produce a decadal survey. The need for high-angular-resolution and high-throughput X-ray optics is strongly endorsed by the National Academies of Sciences, Engineering, and Medicine report, Pathways to Discovery in Astronomy and Astrophysics for the 2020s.In pursuit of this goal, MSFC is continuing to advance the state of the art in full-shell optics. This work will enable the extraordinary mysteries of the X-ray universe to be revealed.

Project Leads

Dr. Jessica Gaskin and Dr. Stephen Bongiorno, NASA Marshall Space Flight Center (MSFC)

Sponsoring Organizations

The NASA Astrophysics Division supports this work primarily through the Internal Scientist Funding Model Direct Work Package and competed solicitations. This work is also supported by the Heliophysics Division through competed solicitations, as well as by directed work from other government entities.